YCK-FL Metallurgical

Installation Manual

Installation Manual

1.Overview

Welcome to choose Xin-Liang YCK series permanent magnetic level sensors.

China Hunan Xin-Liang Electronics Co. LTD has innovatively integrated the most basic electromagnetic induction, and mechanical swing phenomena applied them to the material level measurement and control and developed a brand-new type of level sensors - permanent magnetic level sensors. The newly designed level sensors overcome the problems of being reliable but not durable and high failure rate with rotary paddle level sensors and the issues of being durable but not stable with capacitive level sensors due to the inherent defects with their design principles.

The YCK series permanent magnetic level sensor is a brand new electromechanical level sensor which is reliable and durable. We have received the award of the national invention patent (ZL201110054676.5), the design patent and other patents in China and international patents in major countries and economies such as the United States, Japan, Canada, Australia, South Korea, Russia, Brazil, and others.

Due to a series of unique advantages like high reliability, no maintenance, and long life, YCK series permanent magnetic level sensors have become the upgraded version of rotary paddle level sensors and capacitive level sensors, which provide you a better, more cost-effective and more thoughtful choice.

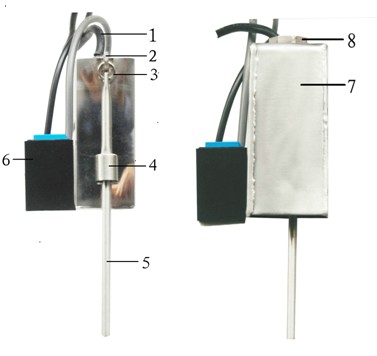

YCK-FL metallurgical special material leveler is developed for the characteristics of working conditions in the metallurgical industry. Separating the probe from the controller, lengthening the probe and adding guards ensures that the positioner works normally and stably in complex environments such as high temperatures and material impacts.

2.Working principle

The permanent magnetic level sensor comprises the permanent magnetic pendulum, electromagnet, electronic modules, and other components.

The electronic module controls the electromagnet periodic power on and off. When the electromagnet is power on, the electric current gives rise to a magnetic field whose driving action pushes the permanent magnetic pendulum to swing outward. When the electromagnet is power off, the magnetic field gives rise to an electric current, which collects signals of the swing motion and converts to electrical signals. The electronic module then assesses the swing status of the permanent magnetic pendulum based on these signals, determines the presence or absence of objects, and then outputs the switch signal after certain delays.

3. Product Features

High reliability and super sensitivity: Compared to the rotary paddle level sensor which is driven by mechanical force, the new sensor is driven by invisible electromagnetic force and has less moving parts, simpler structure, and more reliable signals and eradicates mechanical abrasions and failures. Since the frequency of the detection swing lever in any form of material swing is different from the air, it can detect almost all materials (more advantages especially for powder materials) and needs no adjustment of the sensitivity to different materials to be tested.

Electromagnetic repulsive force and non-stop percussion can overcome the material adhesion and immune from the impact of temperature and humidity, and tremendously improve the reliability, sensitivity, and applicability.

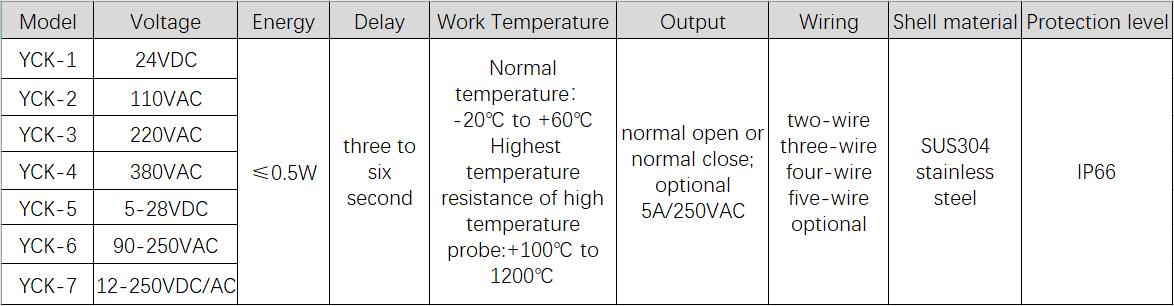

Low power consumption and high safety: the electromagnet needs only instantaneous power, but also improves the power conversion rate through the permanent magnet. The power consumption of each unit is about 0.1 ~ 0.5W, which is about only 1/20 of the rotary paddle model. It is the green low-carbon product with the lowest energy consumption in the current market.

Regarding design, it uses a short-circuit protection device and 24V safety power (usually 220V for the rotary paddle style), which makes the installation, wiring and debugging more comfortable and safer. It avoids the burnout of the electric motor and other fire safety hazards which are common to the rotary paddle style.

Resistance to high temperature and high pressure: it uses all stainless steel shell and static seal which is durable and wear-proof, and overcomes the issues of not resisting compression due to the rotary seal and prone to leak with the rotary paddle style. The sensor has the protection class of IP67 and is dust-free, water-proof and shake-proof. The permanent magnet and electromagnetic coil resistant to high temperature are chosen, which can resist to more than 600 degrees high heat.

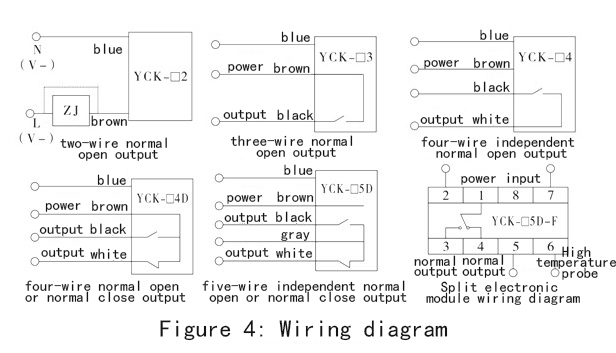

Easy to install and maintenance-free: The new sensor is small and light to delivery. The wiring is flexible (option of two, three, four, five-wire system). It can be easily installed from the top (hanging) or the wall (horizontal), and highly adjustable; no need to worry about material jams and blocks, motor burnout and the sensitivity adjustment. It is self-cleaning and debugging free, and the maintenance and usage costs are the lowest among the level sensors.

Broad application and long service life: As mentioned above, permanent magnet style can be applied to a variety of materials (solid, liquid) level detection. It can adapt to a range of temperature, humidity, pressure, dust and other complex and harsh conditions. It can work safely and reliably with long-term power on, and the service life can be up to 10 years.

4. Scope of Applications

YCK permanent magnetic level sensors can be applied to a variety of materials (solid, liquid) level detection. It can adapt to a variety of temperature and humidity, pressure, dust, and other complex and harsh conditions and environment. It can be widely used in grain and oil, feed, machinery, fertilizer, metallurgy, mining, plastics, machinery, and other industries. It can connect with signal lights, relays, alarms, and other devices and meet a variety of level detection and automatic control needs.

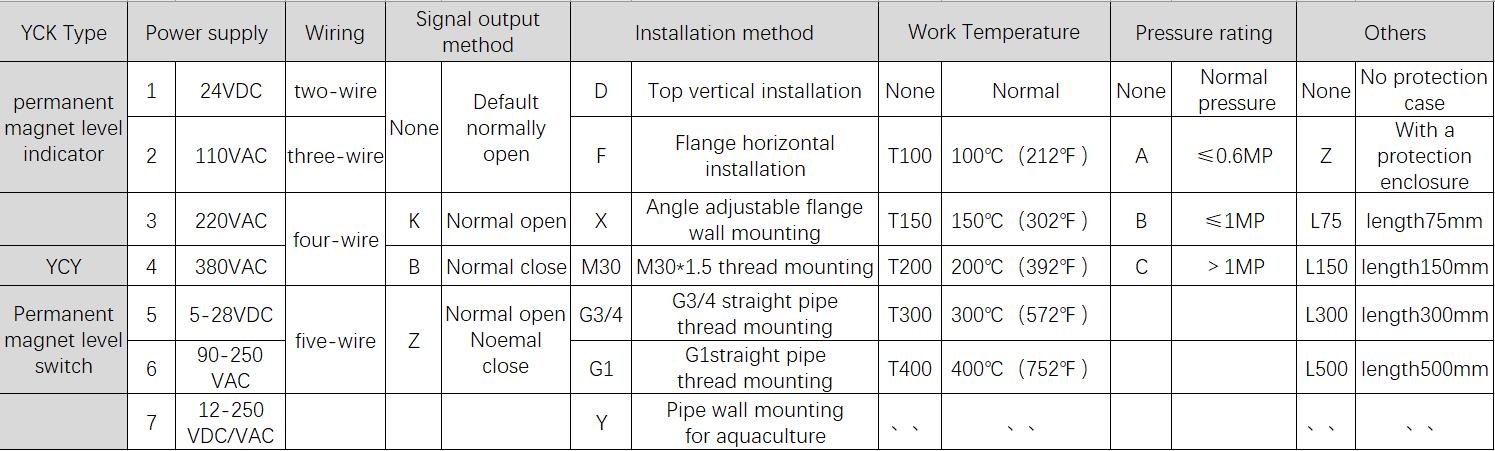

5. Product Model and Classifications

1) YCK-FL permanent magnetics level sensors usually adopts the top loading mode. The position of the nut on the device should be adjusted during installation to keep the leveler in a horizontal direction with an inclination of no more than 15 degrees. The leveler housing should be well grounded.

2) The probe part of the YCK-FL metallurgical special type sensor is placed in the protective cover, and the electronic module is partially installed at the normal temperature outside the warehouse, and connected by a high temperature resistant silicone core (connected by color). The part of the protective cover is generally in the form of lifting. The mounting frame can be as shown in Figure 2. The flange plate is made of DN15 steel pipe, and the fixing method can be flexible and diverse.

3) The wiring method of this product can refer to the wiring diagram. Before turning on the power, please check if the wiring is correct and the voltage is rated. And the loaded current cannot exceed the maximum output current, and no short circuit is allowed.

4) The YCK-1X model product has the relay free output. When the brown wire is connected to V +, blue wire to V-, black line outputs V+, it is the PNP output. In reverse, it outputs V- as NPN output.

5) If the output settings of the level sensors cannot meet the users' needs, one can add an auxiliary relay to extend.

1) Permanent magnetic level sensors delay closure and delay disconnection are generally set at 3-6 seconds. If the user needs other delay settings, please specify the delay time settings.

2) A permanent magnetic level sensor is usually three-wire normally-open. If a user needs other output settings, please specify it separately.

3) The regular length of this product is marked in the installation dimension drawing. Please specify it if you need other measures.

Telephone Number:86-0730-8568883

FAX Number:86-0730-8573861

Address:No.1, Guihuayuan Rd, Yueyanglou District, Yueyang City, Hunan 414002, China

P.C.:414002

Email:1264626991@qq.com

Taobao shop:湖南信量电子