Suitable for feed mill granulation cooling system

The existing material level indicator can not adapt to the high temperature, high humidity and high adhesion working condition of the granulating cooler and the curing device of the feed mill, and often the material is blocked, the equipment is burnt out, the hot feed is discharged, and the feed water is high, It is prone to mold and other phenomena, which not only delays production, but also affects product quality.

★RF capacitance level indicator: It is only suitable for coolers with lower temperatures, and the cooker with a slightly higher temperature will not be used. A layer of plexiglass must be added for partitioning during installation to detect. When the cooler is working, the inside of the wall is hot and cold, and it is easy to condense water droplets. The plexiglass will also adhere to the feed, which will cause the capacitor level indicator to malfunction, and the sensitivity of the capacitive leveler is easy to change with temperature. Thus an error occurs.

★Rotary paddle level indicator: Due to the high temperature, the lubricating oil is thinned. The rotary-type material indicator adopts dynamic sealing. A large amount of water vapor is poured into the body, which may cause the oil seal to fail and become stuck. Moreover, the rotary-type material level indicator adopts the micro-switch output signal due to cooling. The action of the device is very frequent, so the micro switch that is the vulnerable part will fail due to the high temperature, high humidity and high frequency action accelerated wear.

Permanent magnetic level indicator has significant advantages in the application of coolers and cookers

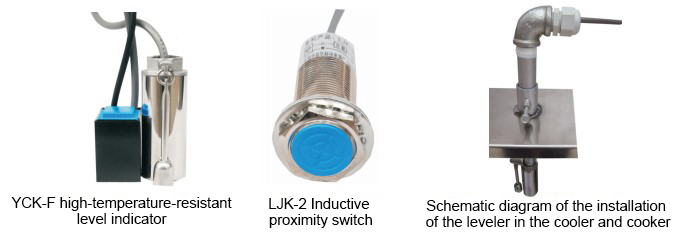

★YCK-F uses split structure: It consists of a high temperature probe installed at a high temperature in the silo and an electronic module installed at a normal temperature outside the silo, which ensures the safety and reliability of the electronic control module.

★YCK-F is made of high temperature resistant material:The high temperature probe and the electronic module are connected by a high temperature resistant silicone cable; the high temperature probe part is made of an electromagnet with a temperature resistance of 250 ° C, a samarium cobalt permanent magnet, a silicone cable and a 304 stainless steel. Therefore, it can work reliably for a long time in a working environment with high temperature, high humidity and high adhesion.

★YCK-F uses a safety circuit: The electronic module uses a safety isolating transformer to isolate and step down, so that its connection to the high temperature probe is in a low voltage environment, safely isolated and short-circuit protected. Indicators are provided on the electronic module for on-site monitoring.

★YCK-F uses a static seal: Both the probe and the electronic module are statically sealed with high temperature resistant glue, which is completely isolated inside and outside, avoiding the defects of rotating, dynamic sealing and leakage of the rotary type positioner, and avoiding mechanical failure.

★YCK-F uses an adjustable mounting bracket: The height of the leveler can be easily adjusted at any time, making installation and commissioning more convenient.